IPP Deltaflex® Flange Engineering

Improved Piping Products, Inc. (IPP) is famous for its Deltaflex® convoluted flange for HDPE piping. Manufacturers of pipe flange since 1979, IPP convoluted flanges have proven to be the perfect partner when joining HDPE pipelines. Under the registered trade name IPP Deltaflex® Flanges – IPP has established itself as a world leader in the engineering, design, manufacture and distribution of piping flange systems.

With more than 37 years of piping industry experience in its IPP Deltaflex® convoluted flange design, IPP has been instrumental in bringing reduced costs and increased performance to flanging systems. IPP Deltaflex® flange technology is an innovative, modern, high-performance flange design, adaptable to steel and all thermoplastic piping systems.

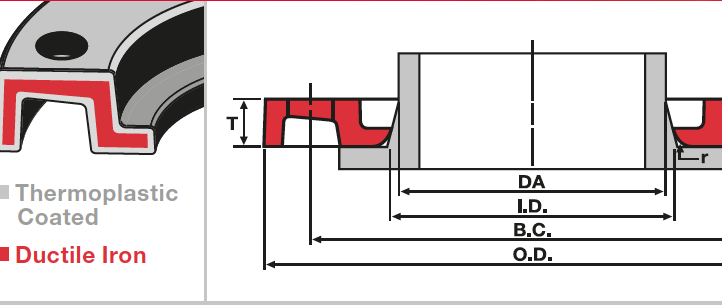

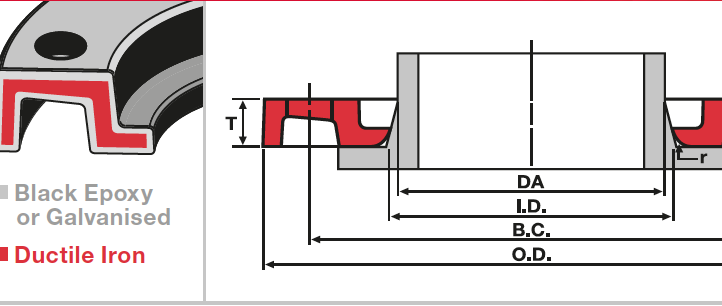

The IPP Deltaflex® convoluted flange range includes polypropylene (PP) encapsulated, thermoplastc coated, epoxy coated or galvanised flanges ideal in most corrosive atmospheres where plain steel will corrode.

IPP Deltaflex® flange technology also significantly reduces the weight of a flange without reducing its pressure performance. Its unique cross section can save up to 40% of the weight over conventional flat plate flanges and the IPP Deltaflex® design principles can reduce the critically high stress levels to a stated safety factor.

IPP has installed millions of its patented convoluted flanges and will continue to innovate and develop safe, functional and cost-effective pipe joints to National and International Pipe Flange Standards for the world piping market.

In response to this IPP Deltaflex® flanges are designed to allowable code stress levels with a safety factor of 2. Even with this generous safety factor IPP Deltaflex® flanges are much lower stressed than the abutting pipe wall material. Therefore a properly selected IPP Deltaflex® flange is not the weakest link in a pipe system when the adjacent pipe wall is closely examined. IPP Deltaflex® flanges are safe, functional structures with an attractive economic dimension. They conserve material and energy resources from manufacture to point of installation. The lower weight translates into several benefits:

- Lower cost of raw material and energy

- Reduced transport costs

- Ease of handling and installation

The IPP Deltaflex® flanges can be substituted for a conventional pipe flange as called out in DIN, ANSI B16.5, B16.47 and AWWA C207. Its unique cross section can save up to 40% of the weight of one of these national pipe standard flanges. Some installation practices have thinned the standard flanges for economic reasons. In these instances using IPP Deltaflex® flanges design principles can reduce the critically high stress levels to a stated safety factor. This performance is achieved by using IPP Deltaflex ® flange engineering to increase the section modulus of the flange without increasing its weight. See figure 1 & 2, comparison of IPP Deltaflex® flange and conventional steel flange.

IPP has installed literally millions of its patented convoluted flanges in the entire spectrum of code controlled commercial and industrial pipe systems. The design technology has consistently been the specification choice of world renowned piping engineers. The IPP Deltaflex® flange truly satisfies the claim of being a modern, high performance pipe flange. Pound for pound there exists no other pipe flange that can safely carry structural loads as efficiently as an IPP Deltaflex® flange.

For more information, please contact us at: info@ippdeltaflex.com